"3D Cable Harness Design" is a component used in Product Lifecycle Management (PLM) services. It involves the design and management of cables used to connect electrical or electronic components in a product.

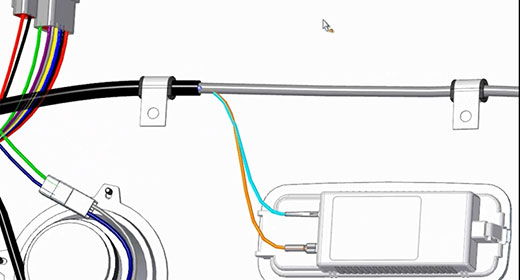

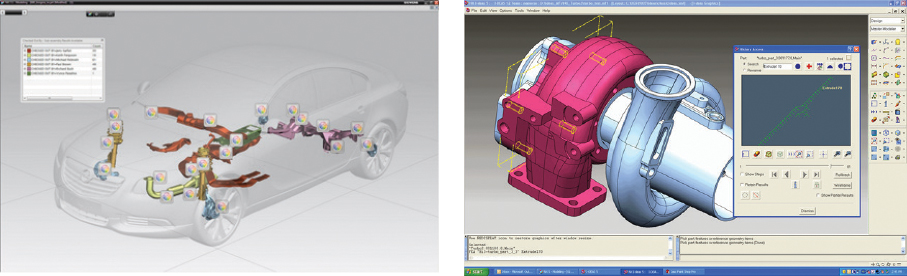

3D Cable Harness Design utilizes 3D models that digitally represent the cable harnesses and connections of a product. These models include cable routes, connection points, cable lengths, and other relevant details. They also encompass physical constraints, electrical requirements, and standards associated with the wiring system.

Key features of 3D Cable Harness Design include:

Cable Management: 3D Cable Harness Design effectively manages cable harnesses and connections. Cable routes and lengths can be calculated automatically to avoid clashes and achieve optimal wiring. This ensures proper cable design and facilitates the installation process.

Communication and Collaboration: 3D Cable Harness Design facilitates communication and collaboration among electrical engineers, manufacturing engineers, and other stakeholders. By working on a common platform, design errors can be reduced, issues can be resolved quickly, and project progress can be tracked.

Efficiency and Cost Savings: 3D Cable Harness Design enables more efficient cable management and installation processes. Through advanced simulation and analysis tools, cable lengths can be optimized, material waste can be minimized, and costs can be reduced.

Documentation and Maintenance: 3D Cable Harness Design facilitates the creation of documentation related to cable harnesses. This documentation may include assembly instructions, connection diagrams, and maintenance guidelines. It enables more effective assembly and maintenance processes.

3D Cable Harness Design is a significant component that simplifies complex cable management processes and optimizes the electrical connections of a product. It enhances product performance, reliability, and manufacturability while also providing cost and time savings.